Supporting Technology

By Tom Billigen

Advancements in technology continue to yield better engines, improved fuel efficiency and extended maintenance intervals. But beyond delivering superior products, technology has fundamentally changed consumers’ expectations, as well as their approach to service and support. The only way to ensure that dealers, technicians and end users are equipped with the tools they need to keep up with these expectations is for manufacturers to incorporate technology into their service and training the same way it is being embraced in design and product development.

During the past several years, the small engine industry has seen significant technological advancements that have opened the door to new market segments and applications. Although this has steered the industry in a promising direction, it also creates challenges for dealers and technicians tasked with providing comprehensive service for new equipment. The key to success lies in plentiful, easily accessible resources that rely on the power of technology to keep up with advancements.

The EFI learning curve

As electronic fuel injection gains traction in the small engine market, it creates the need to train dealers and technicians. To successfully address the concerns and questions of customers, dealers need comprehensive EFI resources. However, simply reading a manual won’t cut it for many technicians. As a result, some innovative manufacturers have developed EFI training opportunities and courses.

Traditionally, hands-on experience works best for engine training, but this is problematic with EFI engines for several reasons. First, working on actual engines limits instructors to hypothetical scenarios since they lack the ability to prompt the engine to generate specific trouble codes. Also, transporting engines is a hassle and can limit where training can take place.

To create a training tool that’s more portable and doesn’t require running an engine, some manufacturers remove the EFI system from the engine. This provides trainees with hands-on learning while the instructor is able to provide guidance and answer questions. However, since the system is not connected to an engine, the training opportunities are, again, limited.

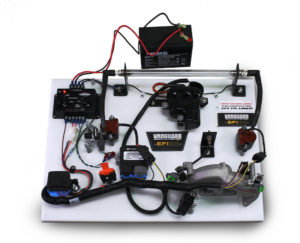

To develop a live, fully operational EFI system without the transportation hassles associated with actual engines, Briggs & Stratton’s training department developed a training board that is fully functional and responsive. The challenge was to create a program that could trick the system into responding as if it were hooked up to a real engine. Through the program, instructors input data that imitates problems and prompts the system to respond, resulting in a fully operational EFI system that’s conducive to hands-on training while also being easy to transport.

To develop a live, fully operational EFI system without the transportation hassles associated with actual engines, Briggs & Stratton’s training department developed a training board that is fully functional and responsive. The challenge was to create a program that could trick the system into responding as if it were hooked up to a real engine. Through the program, instructors input data that imitates problems and prompts the system to respond, resulting in a fully operational EFI system that’s conducive to hands-on training while also being easy to transport.

Tuning in for success

While hands-on experience is often preferred, it’s not always a practical option. When it’s not, detailed videos are the next best thing. To accommodate, some leading manufacturers offer educational tutorials, training sessions and step-by-step videos that cover nearly every engine repair and preventative maintenance topic. In some cases, dealers now have access to a library of more than 100 videos covering everything from the basics of a four-stroke engine and alternator testing to in-depth EFI troubleshooting and step-by-step fuel system repairs.

Beyond video archives that can be accessed at any time, some manufacturers have gone as far as developing an on-site video production studio. This gives the manufacturer the opportunity to quickly respond to questions with a new video tutorial.

Information at our fingertips

Another way in which manufacturers are helping dealers gain the upper hand is with comprehensive online dealer portals. These portals are available only to certified dealers and provide instant answers to the toughest questions via detailed training courses, engine repowering tutorials, EFI diagrams, step-by-step video demonstrations, single-source parts ordering, warranty servicing and more. By providing the most extensive and up-to-date information in one place, dealers are always equipped with the information they need to turn repairs that could have otherwise taken hours into a simple five-minute task.

Of course, dealers aren’t the only ones trying to stay on top of the latest technology. For end users, knowing which problems to tackle on their own and when it’s time to call a dealer is not as simple as it used to be. Additionally, keeping up with maintenance specifications for individual engine models can feel like a moving target as manufacturers continue to innovate and create new designs to extend service intervals, improve fuel efficiency, or increase productivity. To give contractors and operators a leg up, manufacturers are finding new ways to make information more readily available to end users.

One approach has been to include a QR code directly on an engine that – when scanned with a smart phone – provides instant access to model-specific information, including manuals, illustrated parts lists and service information. This technology can also be used to help operators locate the nearest certified dealer. For example, if an operator needs a part, they can scan the code, quickly identify the correct part for their engine model, tap to call the nearest dealer, and then pick it up as soon as that day.

Sustaining progress

As technology continues to yield more advanced and efficient engines, dealers and technicians don’t need to stress about getting the support they need to keep up with the changes. More and more, manufacturers are realizing the importance of embracing technology and innovation as a tool for product development, as well as service and support.

After all, the only way to ensure that consumers are able to fully appreciate the productivity that new technology has to offer is to provide everyone with the resources required to harness it.

Tom Billigen is customer education training manager at Briggs & Stratton.